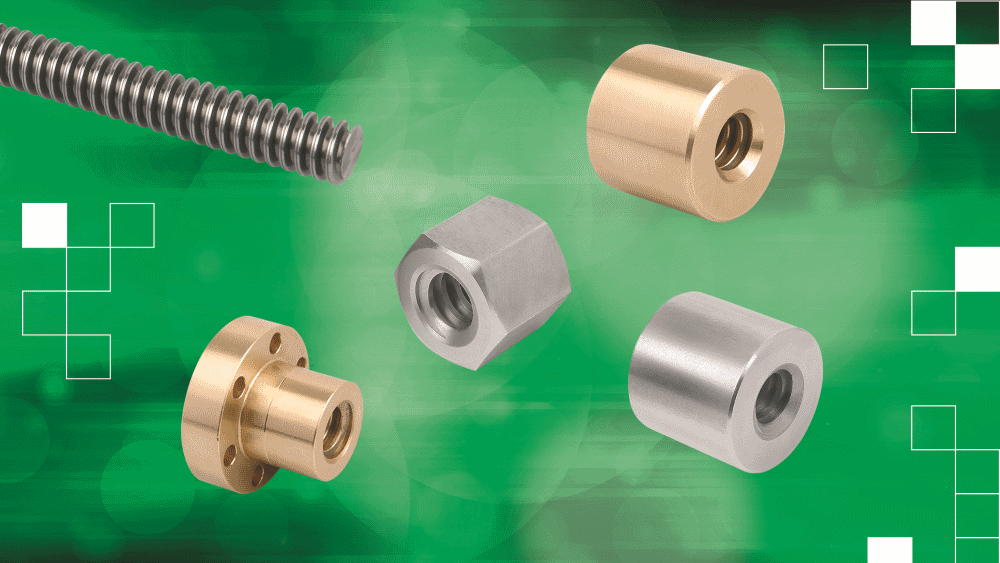

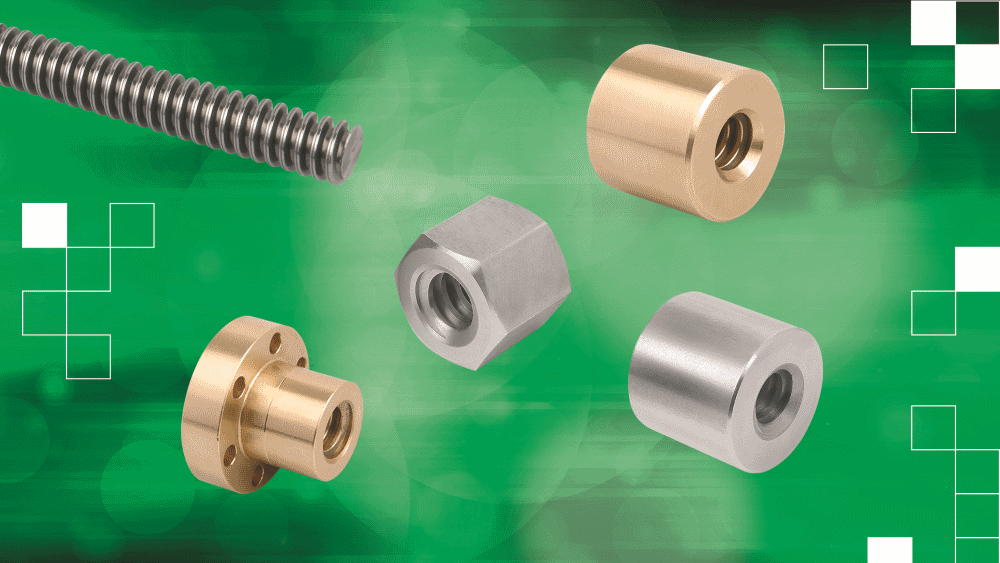

norelem has expanded the product portfolio with additional trapezoidal thread spindles and nuts. In combination, these high-quality components produce reliable trapezoidal screw drives that can be used e.g. in machine tools, presses, linear actuator or lifting equipment.

The trapezoidal thread spindles available from norelem are rolled and not cut. This production method does not interrupt the grain structure of the base material, which has a positive effect on durability. In comparison to cut threads, the surface hardness of rolled trapezoidal threads is up to 30% higher and the tensile strength is increased by up to 12%.

The trapezoidal thread spindles and nuts are available as one or two start, in various pitches and as right or left hand versions. As standard the spindles are manufactured from the low carbon steel 1.0401 (C15) or 1.4305 stainless steel.

The trapezoidal thread nuts from norelem are available as round nuts, hexagonal nuts and with flange. The material is decided by the customers individual requirements - the nuts are available in gunmetal, steel, stainless steel or plastic. The plastic versions provide for good running properties and low noise.

A trapezoidal thread drive - the combination of a trapezoidal thread spindle and trapezoidal thread nut - transmits a rotating motion into a linear motion. This is a feed thread with relatively high friction, which is self-locking in the standard thread range. This has the advantage that usually no separate lock is required in the rest position.

The material combination of a steel spindle and gunmetal nut is recommended for trapezoidal thread drives. This combination offers the best wear properties and has good dry-running properties when lubricant is lacking. For manual drives or for short-term mechanical drives at low speeds and low loads, users can also choose steel as the nut material.