Smart gearbox points the way into the digital future

From gearbox to IIoT

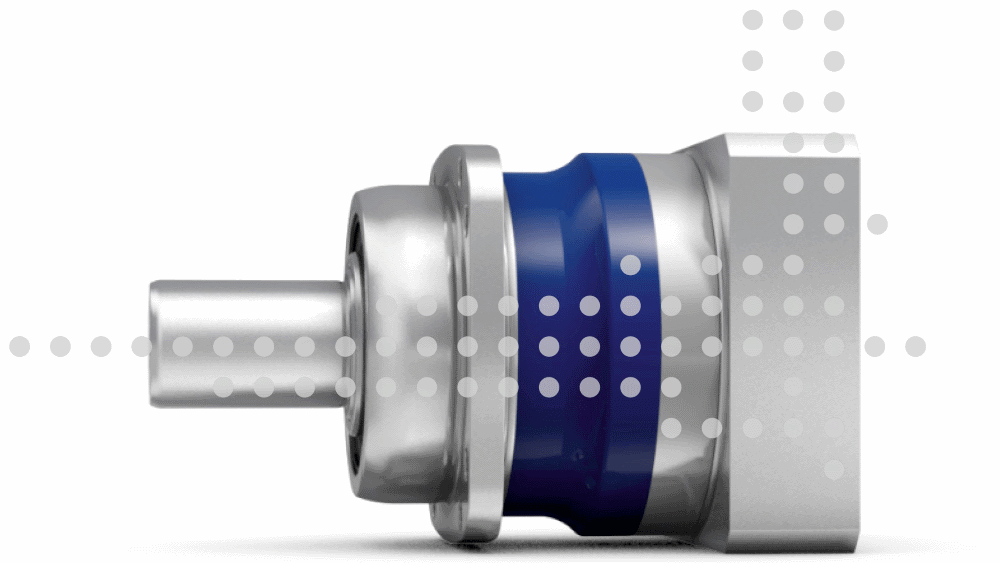

Gearboxes from WITTENSTEIN alpha with “cynapse” have an integrated sensor module that enables Industry 4.0 connectivity © WITTENSTEIN SE

Smart gearboxes from WITTENSTEIN alpha – gearboxes with “cynapse” – are set to make their debut this spring. The integrated sensor module enables Industry 4.0 connectivity. This exciting product premiere is embedded in the digitalization strategy which has been on the agenda at the WITTENSTEIN Group for more than a decade.

WITTENSTEIN alpha GmbH will be becoming the first component manufacturer to bring smart gearboxes to market as standard products – gearboxes with “cynapse”. The innovation will be available for gearboxes in the alpha Premium Line from the launch date and then gradually extended to all WITTENSTEIN alpha series. Gearboxes with “cynapse” are identical to the existing models in terms of design, size and contour, so that a drive solutions which has already been designed needs no further modification. It is the sensor module integrated in the smart gearbox that makes the difference.

From gearbox to IIoT

Thanks to the integrated sensor module, influencing quantities in the process and the environment which impact on gearbox operation can be identified, measured and output via an IO link. In other words, these smart gearboxes allow parameters such as temperature, vibration, operating hours and mounting position to be recorded and communicated to the cloud level using the standardized connectivity of the IO link interface and an IO link master. Both there and in the machine’s immediate environment this information can be used, for instance, to improve the availability and productivity of processes and equipment in condition monitoring or predictive maintenance applications. Gearboxes with “cynapse” thus provide universal connectivity: data flows to their own machine infrastructures as well as to all standard IIoT platforms.

These gearboxes will not be the only exhibits at the WITTENSTEIN booth to bear witness to the key role traditionally played by digitalization, which has already been implemented in several marketable applications like the sensorized Galaxie® Drive System, iTAS® – the modular servo drive system with a web server for automated guided vehicles – or a smart drive system with Industry 4.0 connectivity for heavy-duty electric torque multipliers. The new smart gearboxes yet represent another milestone in WITTENSTEIN’s evolution from a drive manufacturer and mechatronics corporation to a “Leader in Cybertronics”.

Understanding digitalization in a business and social context

Technology leadership is at the core of the WITTENSTEIN brand essence. To help maintain that position, the Group is committed to actively shaping the digital transformation. WITTENSTEIN stepped into the production world of the future back in 2012 with the first visible projects at its Fellbach facility just outside Stuttgart. The next landmark was the opening of the “Digitalization Center” in 2016, which meanwhile comprises 30 or so sensor, electronics, software, data and cloud specialists.

The Center’s digitalization strategy defines four key focuses as the Group makes the transition from a drive manufacturer and mechatronics corporation to a “Leader in Cybertronics”: end-to-end digitalization of the WITTENSTEIN product world, digitalized production of the future, digital customer interaction and the integrative design of a digital work culture. In short, WITTENSTEIN is pioneering the digital transformation with extensive digitalization expertise in manufacturing, assembly, logistics and materials management processes.

Source: WITTENSTEIN SE