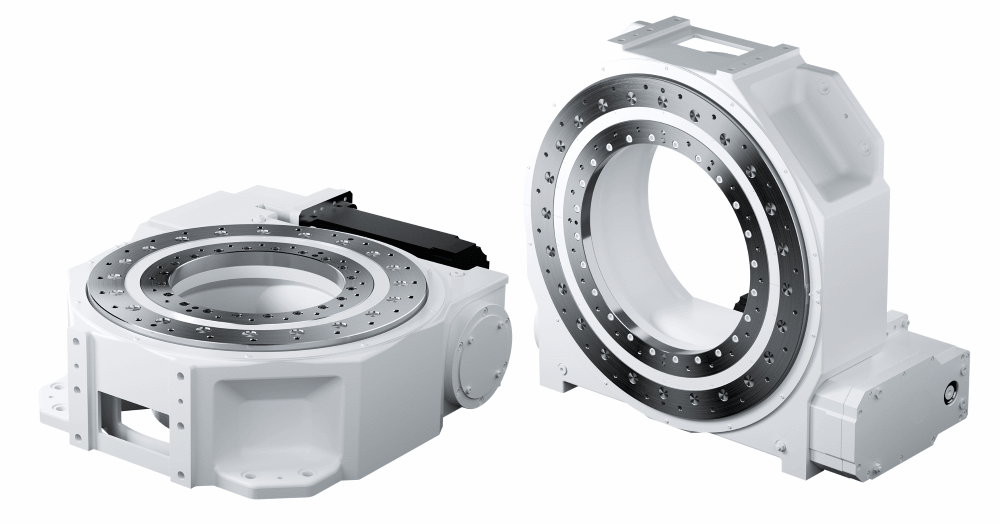

New heavy-duty rings for greater flexibility in production

WEISS showcases its modular next-generation CR series of heavy-duty rings

Automation specialist WEISS to showcase new CR series of heavy-duty rings at automatica. © WEISS GMBH

WEISS GmbH, an automation specialist, will be at automatica to showcase its new CR series of heavy-duty rings. The new models have a modular design, and can be finely adjusted and adapted to a wide variety of applications. New features include multiple gears and a central opening for cable and media entry that is more than twice as large as previous models. WEISS Application Software, W.A.S., ensures easy set-up and start-up — making the rings perfectly prepared for the ever-changing production requirements of the future.

“The modular concept means that users can order the CR heavy-duty rings precisely configured to meet their production needs and avoid paying for unused reactive power,” says Daniel Ansmann, Product Manager for Indexers at WEISS GmbH. At automatica, the WEISS will be presenting the new CR700 and CR900 indexers – the first models in an entirely new family of heavy-duty rings. The models in this series can be more finely adjusted and have around 20% more torque. Users can start by choosing from several different gear ratios, before configuring the ring to suit the relevant load. These configuration options make it possible to coordinate components and prevent oversizing.

Greatest possible flexibility for users

The CR700 and CR900 models each come in two versions, “Precision” and “Dynamic”, depending on which of these two qualities is most important to the user. The “Precision” version has a preloaded drive system to ensure that timing and positioning are as accurate as possible. The key feature of the “Dynamic” version is acceleration with a higher power density. Both versions are the same height. “This gives customers the flexibility to make subsequent changes to the product and load as needed, without having to modify their production facility,” assures Ansmann. The gear unit can be rotated by 90°, enabling both horizontal and vertical use.

Another new feature of this series is the significantly enlarged central opening — 230% larger than in previous models — for the insertion of cables, rotary unions and upright superstructures. The rings are nonetheless more rigid thanks to geometric optimization and the use of the finite element method (FEM) during development. This opens new possibilities in the design of production facilities, for example, industrial robots can be set up directly over the ring to save space.

Ready for Industry 4.0 applications

The new CR700 and CR900 heavy-duty rings are freely programmable using WEISS Application Software, W.A.S., with the relevant settings pre-programmed as standard. The rings can be started up quickly, easily and intuitively, with no special knowledge required. By making the rings modular, WEISS has created the basis for high flexibility in response to frequently changing production conditions. Users can select a heavy-duty ring that perfectly meets their individual needs. Further models are planned.

Source :wire